2.2 Driving the Business

towards Net Zero by 2050

Reducing our Emissions

Achieving the 2030 IMO target ahead of schedule

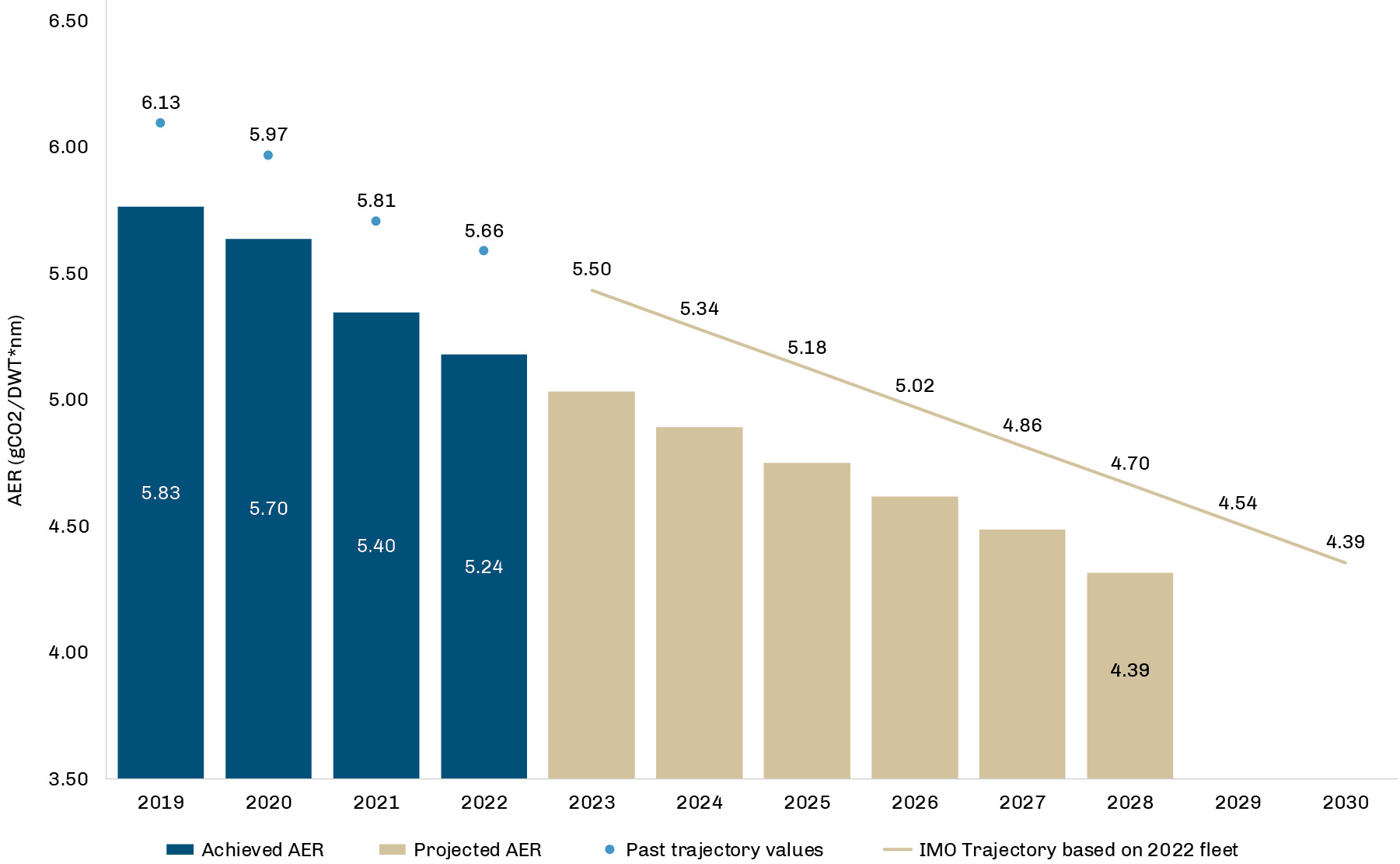

In the short-term, Hafnia plans to deliver at least a 40% carbon intensity reduction by 2028 on our scope 1 emissions – compared to a 2008 baseline – meeting the IMO’s 2030 target two years ahead of schedule.

Multiple scenarios have been successfully tested and will accommodate Hafnia’s intention to comply with IMO’s 2030 target by 2028. These scenarios include 1) a combination of energy savings measures, such as physical energy-saving devices, 2) optimisation of ship operations through education, digitalisation and improved systems, and 3) selling and replacing vessels with more energy-efficient ones.

Improving transparency

In collaboration with the classification society DNV, Hafnia in 2022 developed a digital tool to calculate estimates on carbon emissions for future voyages. This tool enables us to consider the environmental impact of the intended fixture, and obtain an accurate summary of emissions, with class-verified data, following the completion of each voyage.

This provides our teams and customers with improved transparency on carbon footprint and an optimised foundation for making informed choices relating to decarbonisation.

Hafnia Transition Plan to meet the 2030 IMO target ahead of schedule

The scenario is based on the assumption of adding vessels fueled by greener fuels to the fleet (4 Dual Fuel LNG in 2023), a gradual replacement of 16 old ships with newbuilds by 2028, as well as an upgrade of part of the fleet through premium hull coatings and installation of mewis ducts and other energy-saving devices during the drydocking cycles of our ships.

Optimising our vessels’ performance

Hafnia has implemented numerous energy-saving initiatives, which has resulted in overall fuel savings and improved efficiency.

Our vessel-optimisation measures are an integral part of efforts to improve air quality by minimising our emissions.

Hafnia monitors and optimises voyages using digital systems such as Coach and Smartship, while implementing corrective measures to improve underperforming vessels when required. Hafnia is also implementing physical energy-reducing devices on all applicable vessels after calculating the effect and validity for each ship.

The potential emissions’ reduction from these initiatives, installed on the same vessel, accounts for up to 16% in the first year of implementation, and about 10% after five years, mainly due to reduced efficiency of the premium hull coating. We have planned to apply progressively premium hull coating on our entire fleet and will install all possible energy-saving devices when relevant to the vessel.

To date, 61% of the eligible fleet has been fitted with premium hull coatings, reducing 80,000 MT of CO2. Simultaneously, the application of the mewis devices led to an emissions reduction of 11,000 MT.

Energy Efficiency Existing Ship Index (EEXI) regulation

The EEXI determines the energy efficiency of a ship, purely considering its design parameters. From 2023, all Hafnia’s vessels will meet a minimum energy efficiency standard to comply with EEXI regulations. While 86 of our 113 vessels have already been designed to fall below the minimum standard, we will be implementing engine and shaft power limitation devices to ensure all our vessels are compliant with the EEXI regulation by the individual vessels’ compliance date.

Carbon Intensity Indicator (CII) regulation

Further, all vessels will be required to comply with the CII regulation in 2023. The CII measures the vessel’s efficiency in transporting cargo in terms of CO2 emissions. As per the guidelines set by the IMO, the CII of a ship will be rated from A (major superior) to E (inferior performance level), and thus determines the effective operational utilisation of a ship.

In 2022, 108 of our 113 vessels were at or did better than the requisite performance levels and were provisionally graded A, B, or C.

| Physical energy-reducing devices installed on Hafnia Vessels in 2022 | |

| Premium hull coating | Based coating with controlled biocide release keeps fouling at bay when the vessel is underway and during extended idle periods. Low hull roughness equates to better fuel performance |

| Mewis duct | Cylindrical ducts fitted ahead of the propeller, change the inflow angle and speed of water to the propeller, thereby improving propulsion efficiency |

| Propeller boss cap fins | Made of the same material as the propeller. and installed at its rear, propeller boss cap fins break the hub vortex that forms behind the propeller to improve propeller efficiency |

| Biofilm protection | Biofilm protection prevents the formation of biofilm and the growth of algae, barnacles and other organisms, which makes underwater cleaning of the propeller obsolete. This simultaneously reduces fuel consumption. |

| Green oil filter | Filtration system to remove emulsified free water particles and bound water from any oil type, allowing for reduced power consumption and oil waste |

| LED lighting | Replacing traditional lighting with LED lights reduces energy consumption and maintenance costs |

| Fuel eco-nozzles | Devices that improve the propulsion efficiency of the vessel, allowing for saving power |

| Variable Frequency Drive (VFD) | VFDs save energy and improve system efficiency by enabling electric motors to operate at various speeds. Hafnia uses VFDs on engine room vent fans, seawater pumps, scrubber pumps and a steering gear motor |